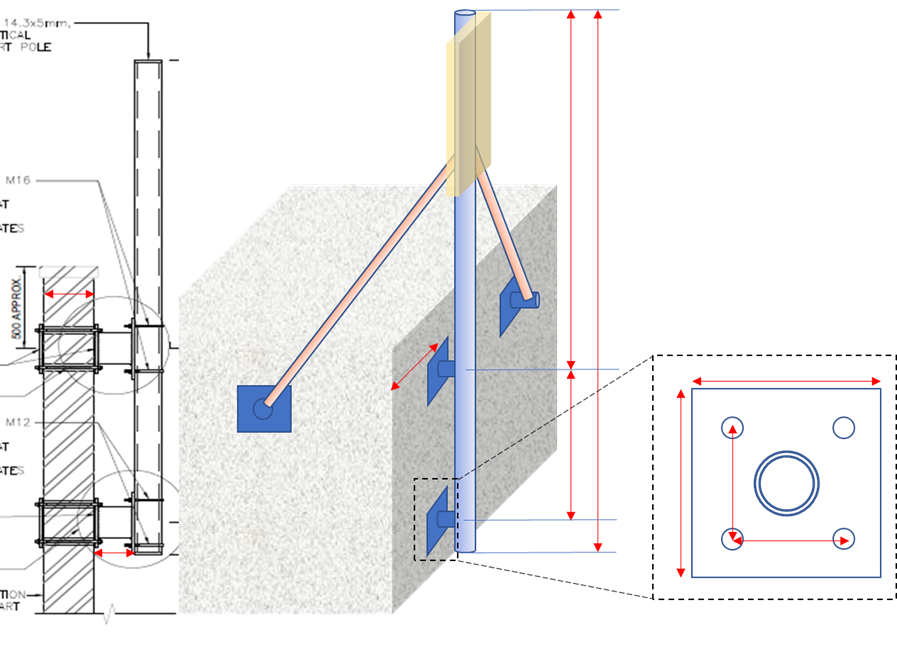

One method commonly employed for the installation of telecommunication ancillaries involves mounting poles directly onto walls at specific elevations, utilising the wall as the primary structural support for bearing the ultimate load reaction from the steelwork. However, the suitability of the wall to support additional loads, such as elevated antennas, raises concerns, particularly regarding concrete and masonry walls. While concrete walls offer greater inherent strength compared to masonry walls, the installation of antennas poses challenges to both types of walls due to potential structural inadequacies.

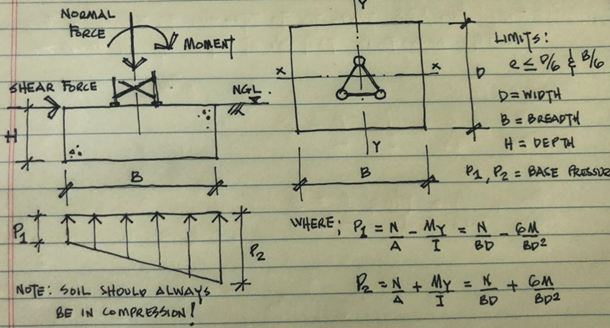

The wind and weight loads of the telecommunication ancillaries are transferred to the wall in form of tension, shear and sometimes torsion through wall anchors, potentially leading to the masonry wall failure. Shear failure and flexural failure are the two primary modes of failure observed in masonry walls.

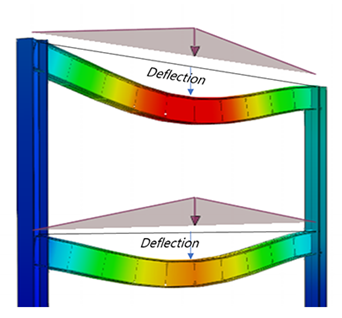

- Shear failure occurs when the shear forces acting on the wall exceed the wall shear capacity, leading to horizontal cracks and potential sliding or tilting of wall segments. This failure can manifest as in-plane or out-of-plane shear, with the latter being more likely in walls supporting elevated antenna poles due to the pull-out force induced by the anchors.

- Flexural failure is characterised by bending of the wall when the wall’s flexural strength is exceeded. This failure can occur parallel or perpendicular to the wall bed joint depending on the loading direction and wall boundary conditions. The characteristics flexural strength of masonry varies along the plane. The characteristics flexural strength of masonry along the plane perpendicular to the wall bed joint is three times of that parallel to the wall bed joint, highlighting the importance of conducting flexural checks in both planes to ensure structural integrity. Thorough load analysis and adherence to robust design practices are essential for mitigating the risks of shear and flexural failures, thereby enhancing safety and reliability in telecommunication infrastructure installations. Prioritising proactive measures is imperative to meet the demands of modern telecommunication while ensuring long-term resilience and public safety.

At KA Engineering Group, we leverage our extensive engineering experience to consider, advise, and optimise each site, ensuring cost-effective design, installation, and maintenance for build contractors and efficient utilisation for operators. Contact our expert team at: info@ka-engroup.com to learn more and discuss how we can best serve your needs.