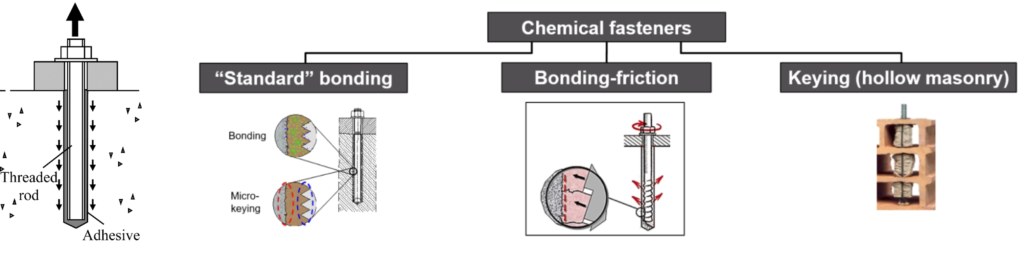

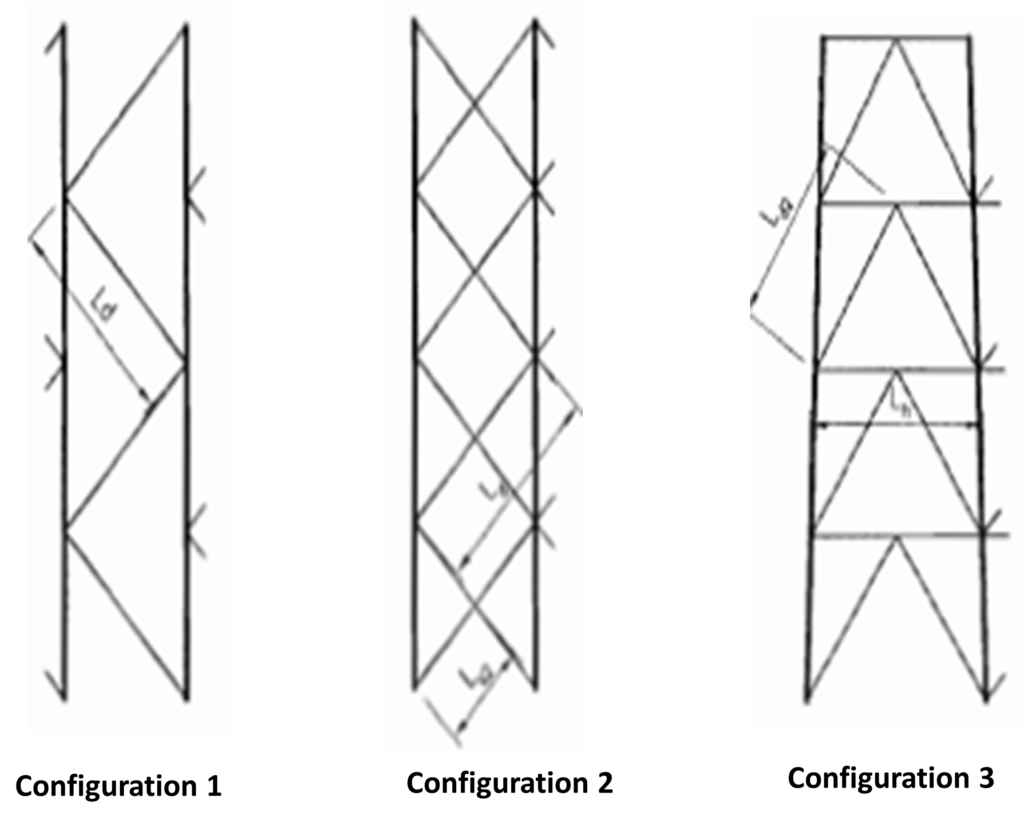

The choice of anchor and the method used to calculate its capacity are essential for a successful installation. One critical factor in anchor calculation is the condition of the concrete into which it is installed. Concrete can be either cracked or uncracked, and this distinction significantly impacts anchor performance.

Cracked vs. Uncracked Concrete

Uncracked concrete is where the tensile stress in the concrete is smaller than the tensile strength of the concrete.

Cracked concrete will be seen on reinforced-concrete members under service conditions and in the tension zone.

Concrete is typically assumed to cracked under normal service load conditions, but when can it be assumed to be uncracked?

Design for uncracked concrete conditions is permitted only when the designer can demonstrate with stress analysis that the concrete around the vicinity of the anchor, will remain uncracked throughout its service life in all future loading conditions. This is typically only the case in members or parts of members which will not experience significant tensile forces.

Conclusion

Distinguishing between designing fasteners for cracked or uncracked concrete is crucial for ensuring the structural integrity and safety of anchors. It is important to follow the codes and standards meticulously when designing and installing these anchors.