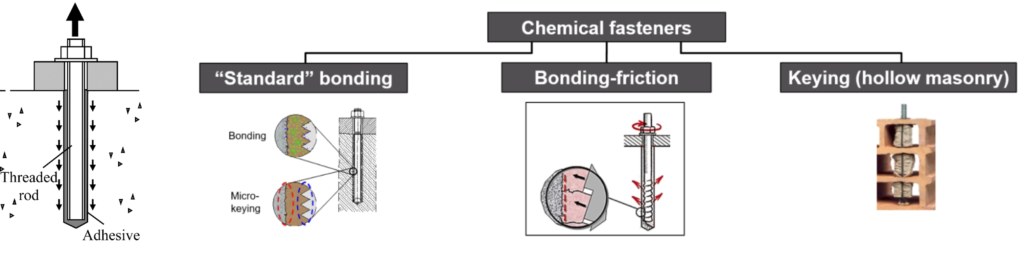

A short discussion on chemical fasteners, continuing our series of posts on fastening technology. Chemical fasteners transfer tension load to the borehole mainly via adhesion. The components are connected to one another to form an adhesive bond.

Advantages:

- High load-carrying capacities

- No expansion forces (ideal for fastenings near the edge)

- Suitable for anchoring in solid and hollow building materials (hollow building materials require a mesh sleeve)

- Sealing function

Limitations:

- No immediate load-carrying capacity (curing times)

- Special assembly requirements:

- Thorough borehole cleaning (prevent high load-bearing capacity losses)

- Components must be mixed completely

- Processing and ambient temperatures affect the curing time

- Special storage requirements:

- Storage period

- Heat sensitivity

We will discuss more on failure modes of fasteners in subsequent blogs. Stay tuned.

At KA Engineering Group, we leverage on our extensive experience to design and recommend most efficient fastening solutions for new as well as existing systems in telecom construction.

Contact our expert team at info@ka-engroup.com to learn more and discuss how we can best serve your needs.