A structure, before being built must be analysed to ensure it can serve its intended purpose and resist any form of load it is subjected to. Before considering the design of any structure, a clear understanding of what loads it will be subjected to is required. This brings us to the question, what are loads?

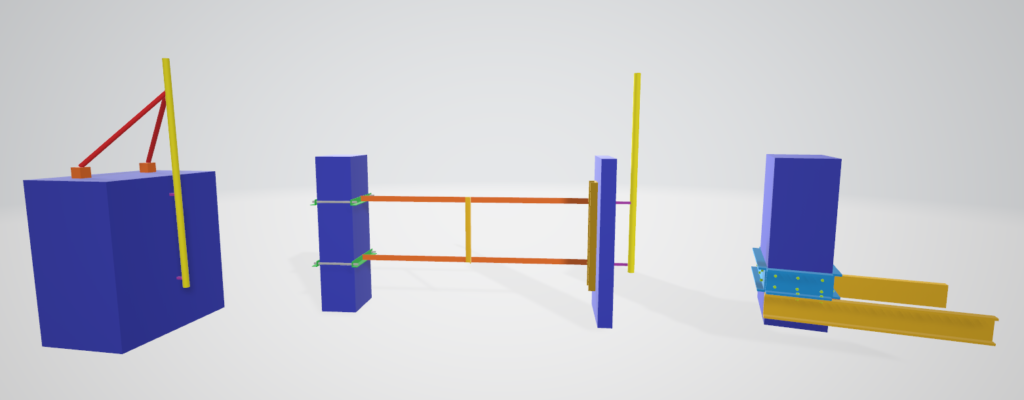

Loads in simple terms are forces that cause stresses, deformation, and displacement of a structure. When not properly catered for, it may fail the entire system. Loads acting on a structure can be classified into three main categories:

- Dead loads: These are also known as permanent loads. They are primarily due to the self-weight of the structure and any other constant loads transferred to the structure throughout its life span.

- Live loads: This is the opposite of dead loads. They are loads on a structure that are constantly changing. An example is the load due to people walking in a building.

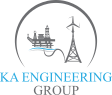

- Environmental loads: These are loads on a structure because of the topography or weather conditions. They include wind loads, snow loads, earthquake loads, etc.

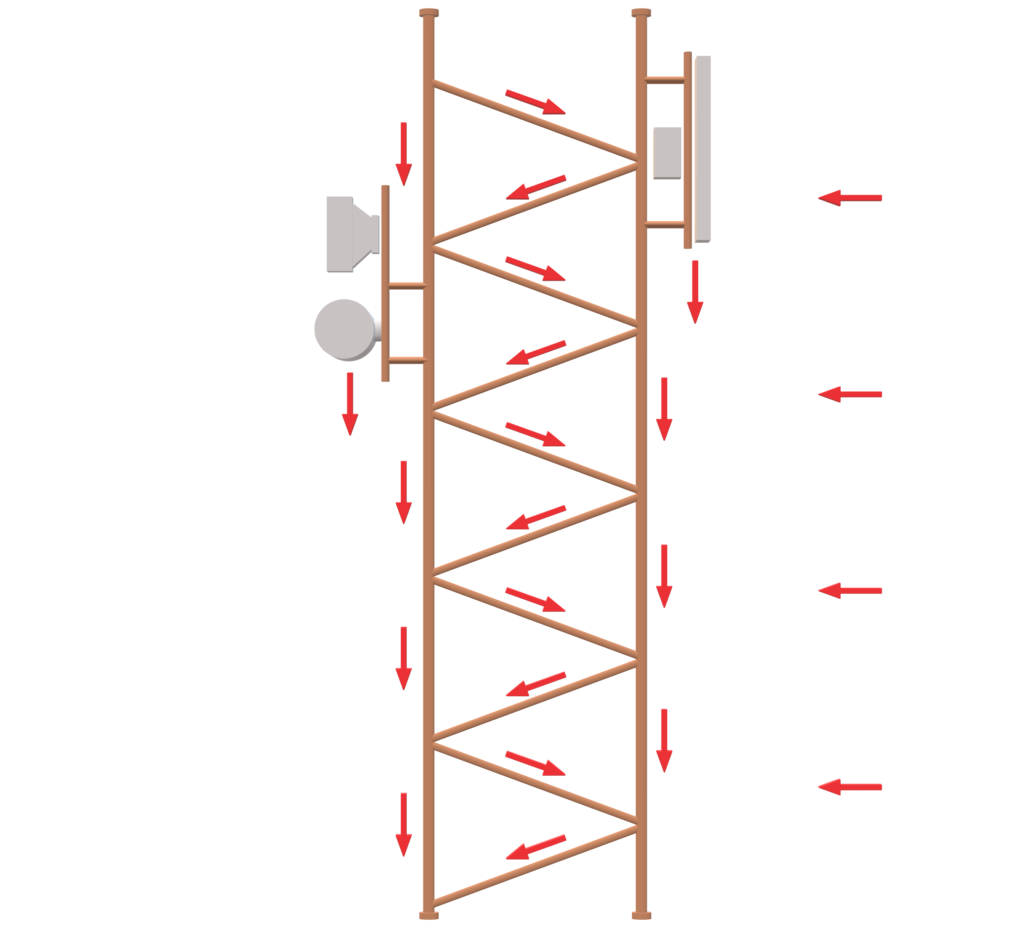

An engineer needs to understand these loads to be able to effectively design the structure to fit. However, understanding what these loads are isn’t enough. There is also a need to identify the path these loads will be transferred through in the structure to properly design an efficient and safe structure.

Different loads move in different directions, and the main function of the load path is to ensure that any loading on the structural system is transferred through connected members safely into the foundation. The foundation then forms the final link in the load path by distributing all the loads safely to the earth.

At KA Engineering Group, we leverage our extensive engineering experience to accurately design any form of telecoms structure ranging from complex GDC to basic DD analysis. We take responsible steps to consider, advise, and optimise each site, ensuring cost-effective design, installation, and maintenance for build contractors and efficient utilisation for operators.

Contact our expert team at: info@ka-engroup.com to learn more and discuss how we can best serve your needs.